Christopher7878

New Member

Hi

This business/inventory question comes up again now but I still don't know how to answer it. Please recommend something thanks

I don't even know how to write the question so let's start with this...

Base on the current counted inventory then how many units and of which model can be built?

Example: Either 5 units of A model, 10 units of B and 15 units of C or 4 A, 9 B and 17 C.

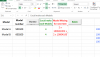

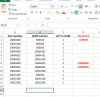

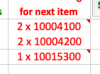

I thought of an excel workbook with multiple sheets and 1st sheet is the model list or dashboard. Where the "how many" and "which model" is answered.

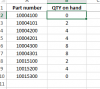

The 2nd sheet list all the parts and qty on hand, and maybe the 3rd column lists which BOM or model that a part is in or maybe put this info on the 3rd sheet.

Then if all the parts and subassemblies needed for a model are on hand then we will know how many units of a model can be built, shown on the 1sr sheet.

But then what about models that short only a few parts that if we buy those parts then we can complete those models? We would like to know that on the 1st sheet too.

This business/inventory question comes up again now but I still don't know how to answer it. Please recommend something thanks

I don't even know how to write the question so let's start with this...

Base on the current counted inventory then how many units and of which model can be built?

Example: Either 5 units of A model, 10 units of B and 15 units of C or 4 A, 9 B and 17 C.

I thought of an excel workbook with multiple sheets and 1st sheet is the model list or dashboard. Where the "how many" and "which model" is answered.

The 2nd sheet list all the parts and qty on hand, and maybe the 3rd column lists which BOM or model that a part is in or maybe put this info on the 3rd sheet.

Then if all the parts and subassemblies needed for a model are on hand then we will know how many units of a model can be built, shown on the 1sr sheet.

But then what about models that short only a few parts that if we buy those parts then we can complete those models? We would like to know that on the 1st sheet too.